Heavyduty-

Mixers

Find the perfect

HighPerformance Mixers

High performance mixers

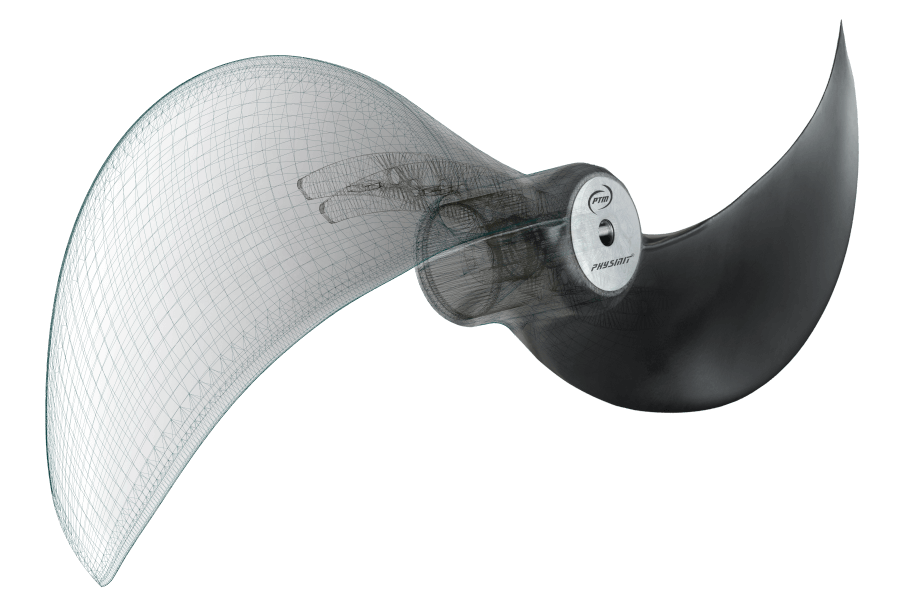

PTM propellers are developed to meet the highest standards in terms of durability and performance. The development of our products therefore includes a solid technical basis coupled with many years of application knowledge and the use of high-quality materials.

The result speaks for itself: high-performance propellers that meet all requirements in terms of service life, ease of maintenance and functionality. Quality made in Germany.

Research and Development

You need a high-quality agitator for demanding tasks. We therefore make no compromises when it comes to service life, ease of maintenance and functionality. Our own research and development team designs and optimizes our agitators. This starts with computer-aided technical development through to field tests of all components.

Inspired by the idea of developing a propeller that combines near indestructibility with maximum functionality in a single product.

The design of conventional propellers results in cords, ropes and fibres accumulating between the propeller and the mixer housing because of the pressure ratios. This subsequently leads to damage both to the propeller and the machine.

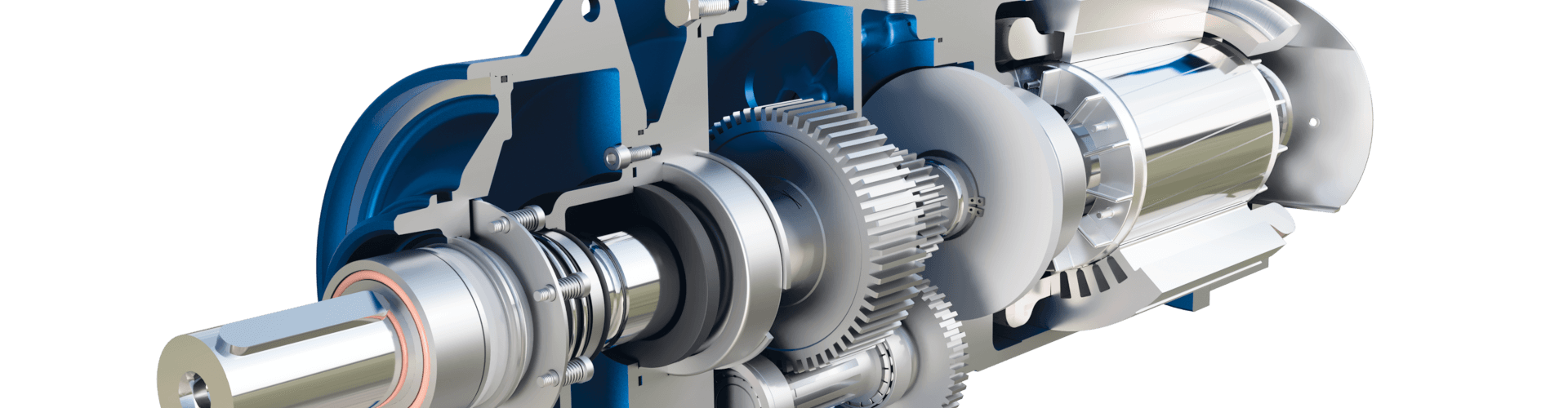

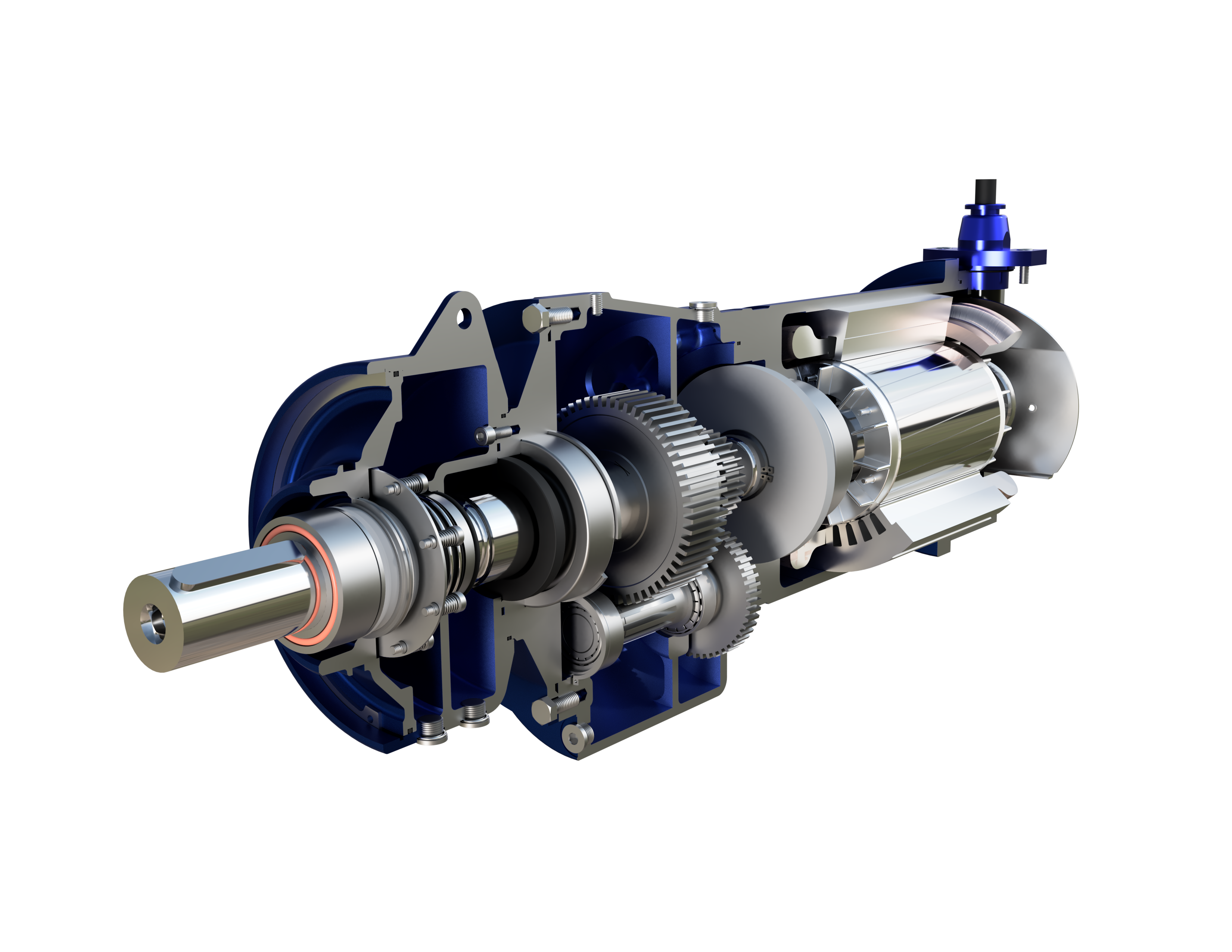

A key component of a mixer is without doubt the drive unit. This is why PTM does not use standard motors but has instead relied for many years on tried and tested submersible motors which have been specially developed to meet the requirements of biogas applications and optimised by many years of practical experience.

The reliability of a mixer depends on the high quality of the seal protecting the machine from the medium. To ensure a mechanical seal functions correctly it is vital that the spring presses on the sliding surfaces with sufficient force. In traditional designs, however, the spring mechanism required is located in the area that can be affected by the medium.

Our Commitment

Many Years of Experience

A sophisticated agitator cannot just be developed on a computer. We know that in addition to a solid technical basis, only broad application knowledge and continuous experience can give a machine real practical suitability for the toughest applications. Based on our research and development using modern computer-aided analyses, all features have been developed and implemented under real conditions, without compromise.

Best Materials

These enable outstanding and durable products. When developing our technology, we have therefore made sure that the materials used meet the highest requirements in terms of wear, durability and functionality.

The material makes all the difference.

This applies particularly to the critical points on the agitator such as the propeller, gearbox and mechanical seals.

Premium Suppliers

In order to be a reliable premium long-term partner for you, we at PTM have created an appropriate environment for this. We rely on companies that are characterized by outstanding technological expertise and the highest quality standards. As a result, you can be sure that you will be able to purchase machines and spare parts of the quality you are accustomed to, even after a long time.

Quality Control

Quality and reliability are the guiding principles of our company. This is why every single agitator is subjected to a critical testing process before delivery to the customer. We check the functionality according to the highest quality standards, specifically and for every machine.