Research and Development

Reliable components

The PHANTOM is the most efficient submersible mixer in its class. It is clearly superior to fast runners or conventional slow runners in demanding applications. Its unmatched durability and excellent thrust to power ratio have not been achieved by chance. Rather they are the result of the interplay of a large number of optimised components.

PHANTOM – your success is our goal!

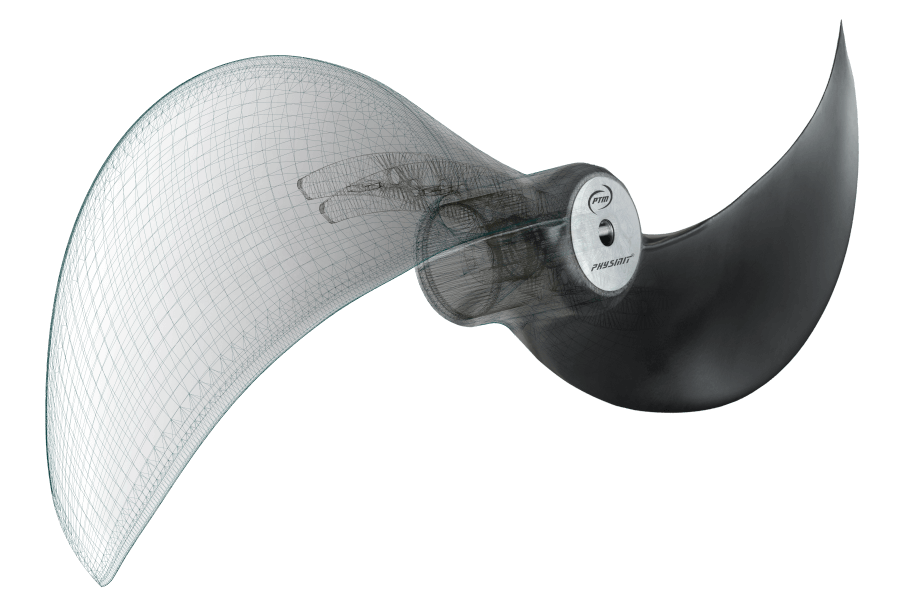

Heavy duty propeller

Inspired by the idea of developing a propeller which combines in one product near unbreakability on the one hand and a high level of functionality on the other, with the help of state-of-the-art simulation methods, our engineers developed a kind of propeller characterised by the utmost efficiency and effectiveness.

Mixers in biogas plants are subject to particular requirements. In particular, long fibres and mineral components like sand and stone often cause damage to conventional propellers in practice within a short period of time. The consequences of this are a short product life and high costs.

For us, it goes without saying that a propeller should have no noticeable wear even after years of use. The PTM propeller is made out of the extremely wear-resistant Physinit®.

Physinit® is a material which is far superior to any metallic substance in terms of durability and resistance to wear. We are so confident about this that we are the only manufacturer of submersible mixers who will offer you a warranty of up to five years. Absolutely unbreakable, it sets a new standard in terms of economy and energy efficiency. (You will never want to use propellers made from conventional materials again)

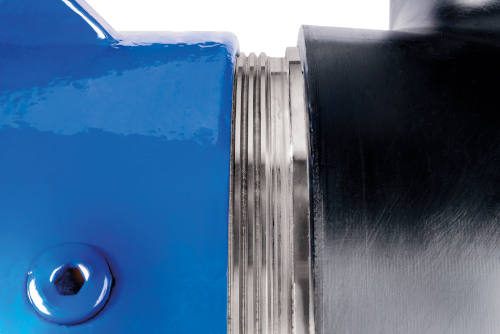

Heavy duty cleaning thread

Conventional propellers are designed in such a way that strings, ropes and fibres accumulate due to the pressure ratios between the propellers and the mixer housing. This causes damage to both the propeller and the machine.

This effect often manifests itself in large gaps, which in turn have a significantly detrimental effect on the mechanical seal of a machine, because the fibre materials can then reach the seal directly and without obstruction. Due to this fact, it is not uncommon for the machine to fail after just a short time with considerable damage.

PTM has developed an innovative technical solution to face this challenge. This takes the form of a conveying and cutting unit arranged behind the actual propeller in the form of a thread, which protrudes into the machine housing. This sophisticated technology reliably prevents fibre material from entering into the gap. The functional principle is based on the fact that the conveying thread rotates in the opposite direction to the propeller and thus any material that finds its way in is reliably and systemically transported out again.

There is thus no way for fibres to reach the area of influence of the mechanical seal and they can therefore do no damage there. The equipment also preventively protects the propeller and mixer housing. Enlarged gaps and strings are therefore a thing of the past. This increases the operating life of your mixer and makes your plant significantly more economical.

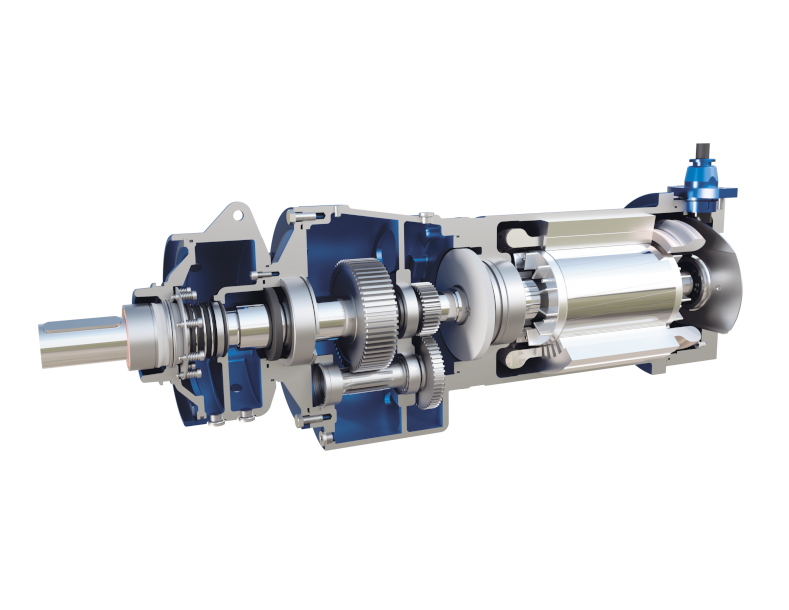

Heavy duty drive unit

The drive unit is undoubtedly a vital component of a mixer. PTM therefore does not use any standard motors, but has instead for many years relied on proven submersible motors specially developed to meet the requirements of biogas and optimised by many years of practical experience.

These are characterised by high thermal and electrical power reserves. The unique cable feed is designed as a connector system which makes it possible to separate the machine from the connector cable, for example for maintenance work, without a problem. So that this can reliably prevent the incursion of moisture, the single-wire feed is longitudinally water-tight. In this regard too PTM has had a unique selling point with excellent functionality for many years.

As energy efficiency is becoming increasingly important to public funding institutions such as BMWI, KfW or BAFA, only highly energy efficient motors such as IE-3 or IE-4 are eligible for a possible funding grant. The reduction of the engine speed is carried out by an extremely robust and at the same time efficient spur gear unit. Generously designed gear components provide the basis for this. Practitioners know that oil quantity and oil quality are decisive factors for the best possible operating life. We have implemented this requirement into our product in an optimal manner.

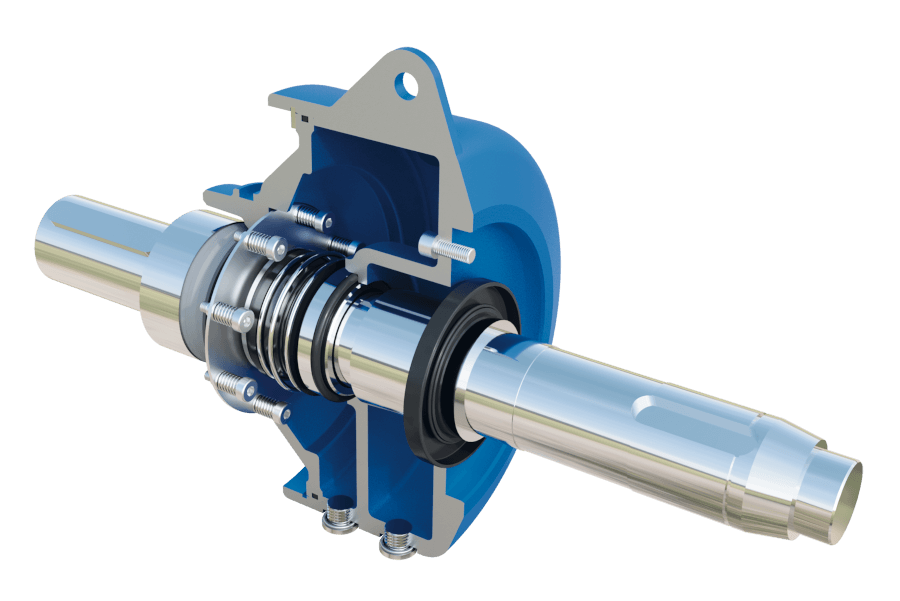

Heavy duty mechanical seal

The bedrock of a reliable mixer is the high-quality seal between the machine and the medium. A prerequisite for the functionality of a mechanical ring is that the spring presses the sliding surfaces together with sufficient force. In conventional designs, the necessary spring mechanism is in the medium’s area of influence.

For media with a high-fibre content, this often leads to these designs failing, as the spring mechanism becomes damaged thereby. Therefore, PTM has arranged the spring mechanism in an area inside the machine.

The spring mechanism having any influence on the medium is thus effectively and safely ruled out. The mechanical seal consists basically of a dynamic sliding surface and a static slide ring made of highly resistant silicon carbide, technically sophisticated and safe.